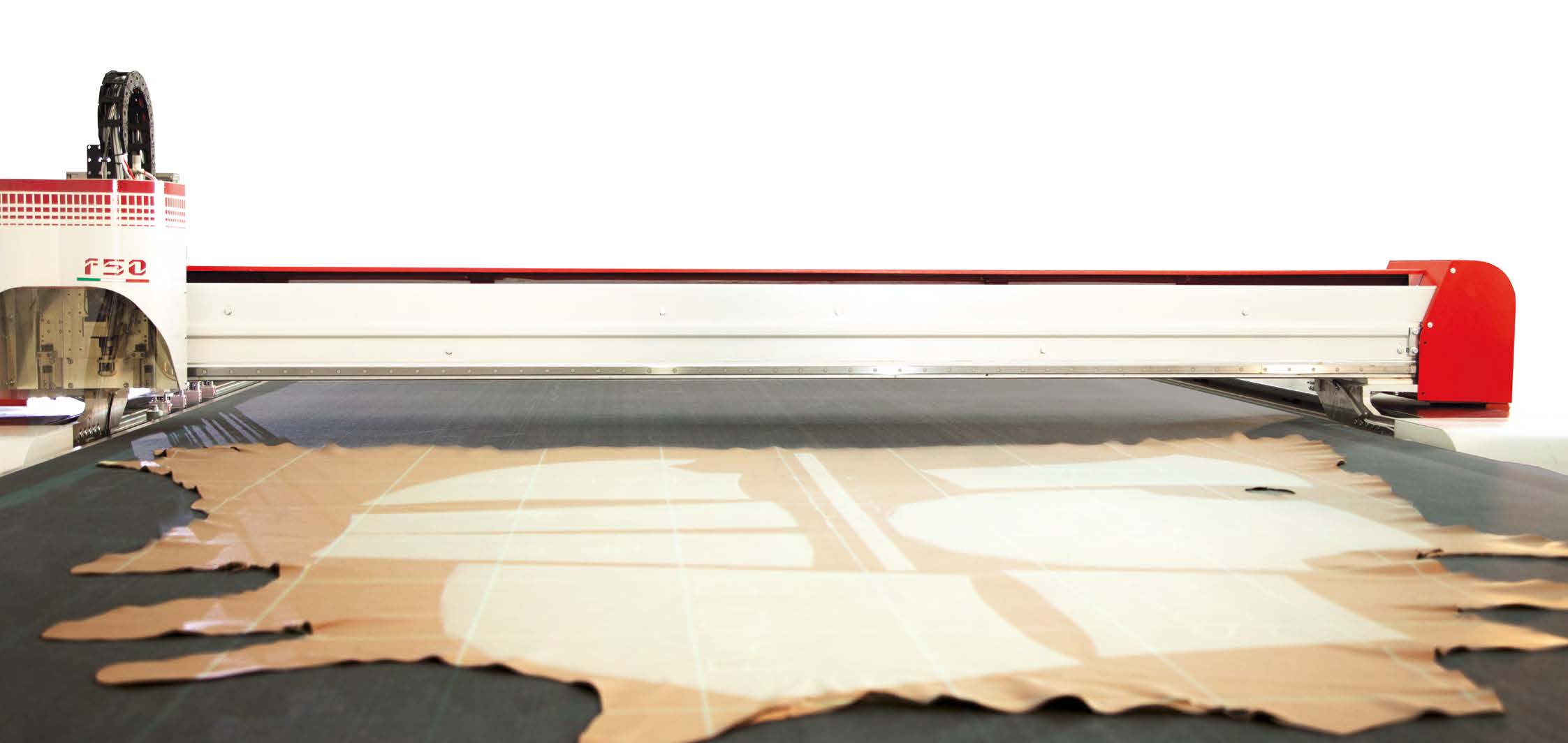

Augusta F50

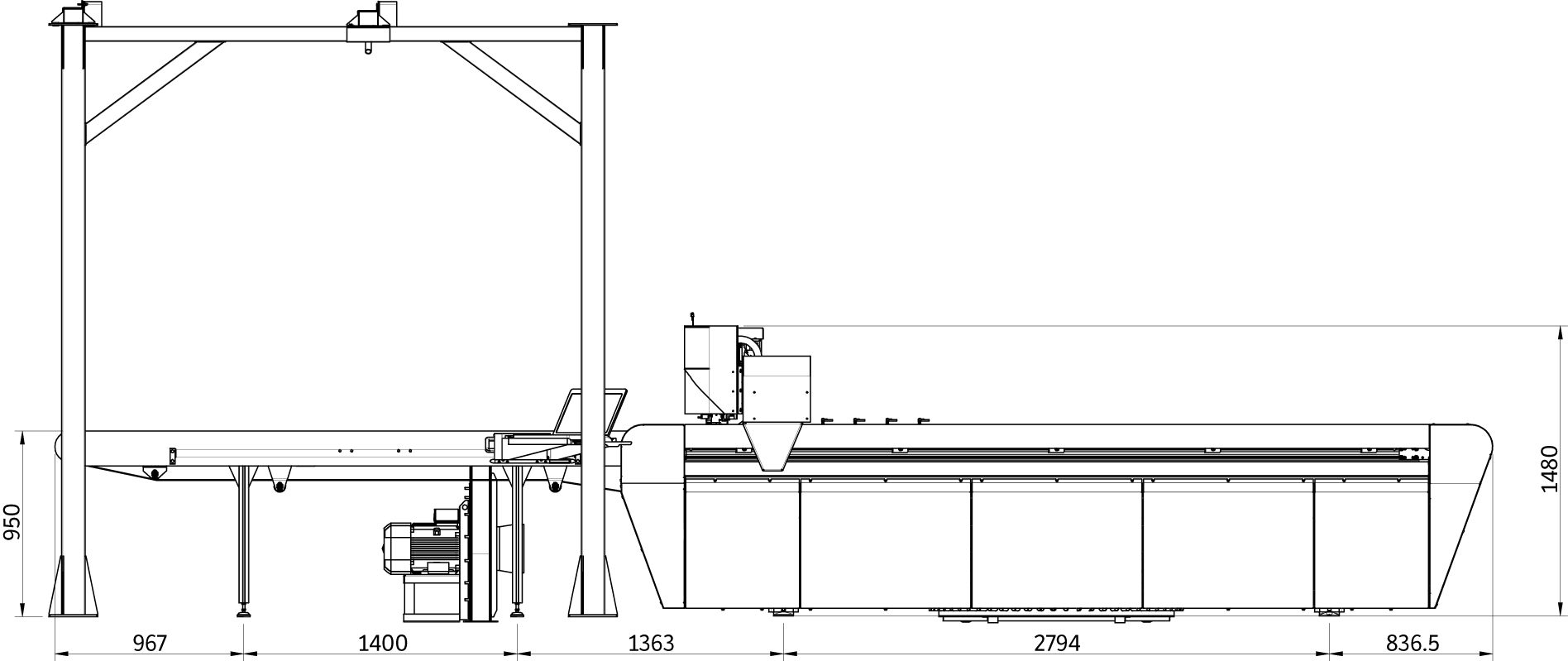

| Workpiece passage | Up to 50 mm | |

| Tool change | Up to 4 positions | |

| Work area | Conveyor | Fixed worktable |

| X 2800 – Y 1600 mm | X 2800 – Y 1600 mm | |

| X 2800 – Y 2800 mm | X 2800 – Y 2800 mm | |

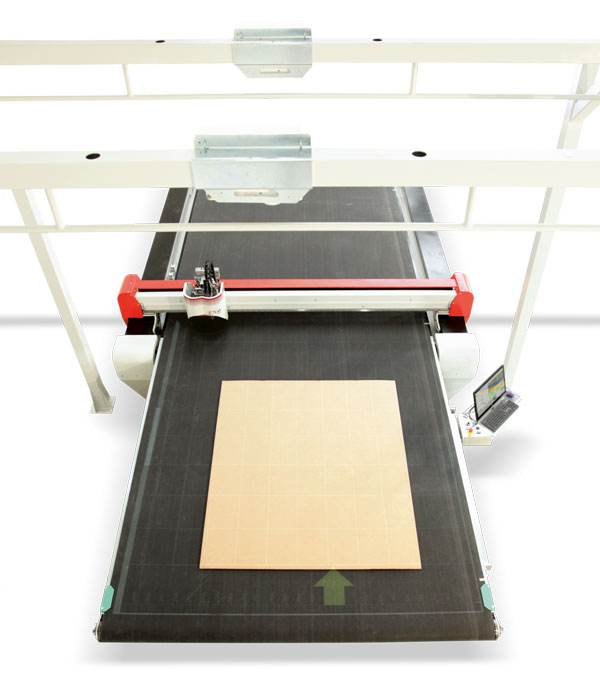

Optional machine automation with automatic loading and unloading systems.

Leather

Rubber

Paper / Cardboard

PVC

Polyurethane Foam

Gaskets

The bearing structure consists of a steel/aluminum base well ribbed and especially rigid. The particular structure, with very broad base, has been designed to ensure stability to the machine and precision in cutting phase in all working conditions.

Stability

The mobile gantry structure consists of a solid single block which can be anchored to the base and slides on prismatic guides equipped with recirculating ball bearings of the highest quality.

Precision

The combination of a sturdy Gantry structure and a perfect mechanical dynamics allows to obtain the highest positioning precision, by maintaining very high speed of movement with maximum results in terms of quality and finishing (Brushless Motors).

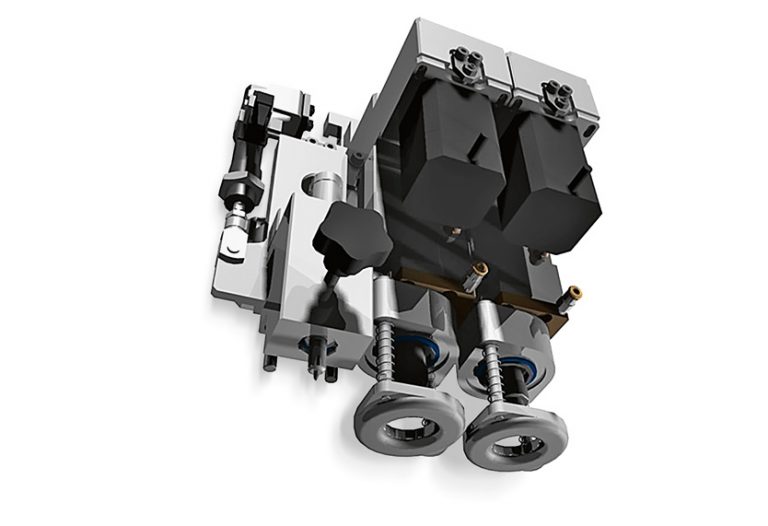

The new working units make the machine flexible and configurable according to cutting requirements.

AFT Unit

Head equipped with independent Z axis of positioning and air-cast to cut the working area.

Fixed or tilting blade cut controlled and activated by CNC with automatic tool change.

ISO 10 connection.

FP Unit

Double roto-translating die-cutting unit (RPM 1700) equipped with controlled Z axis of positioning and with pneumatic launch during processing phase. The units have an internal section to remove the die-cutting scraps. The Pen, with manually removable cartridge, is collocated on the FP unit.

The unit can be equipped with a device for the positioning of shaped die-cutters. Manual die-cutter change.

Applications

Naval sector

- Packaging

Leather and fabric

Polymeric materials

Aeronautics

Furnishing

- Automotive

Industrial gaskets

BLADES FOR LEATHER CUTTING

BLADES FOR POLYSTYRENE FOAM CUTTING

Blades for paper and cardboard cutting

Automatic

controlled tool length

The device allows the operator to check automatically the length of blade or milling cutter to be used.

Automatic

tool change

Availability of up to 4 tools configurable according to customer requirements.

The worktop, which is highly flexible and configurable, has micro-perforated panels that ensure not only the maximum flatness during cutting phase but also the best blocking of the material. The worktop consists of independent vacuum areas (up to 144) selected by CNC.

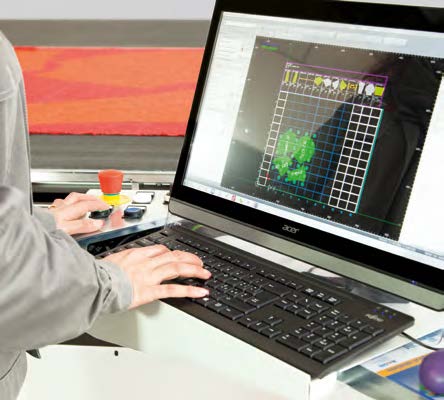

The SD Software Design is a completely modular software including several packages that can be implemented. It has been designed to make the use of machine easier and more intuitive.

Positioning laser

The laser enables the operator to position the sheet to be cut, simply and rapidly, without need of external geometric reference.

Print marks

A high resolution camera enables identification of references on the printed material and consequently adaptation of cutting program.

Video projection

It optimizes at best also small amounts of material, by projecting the shape to be cut on the machine worktop.