Customer need

An important French customer, leader in the production of kitchens and bathrooms, has commissioned us an automatic loading and unloading system for a coating line of large and heavy panels.

Goal

- Automatic loading and unloading and panel overturning

with automatic process - 180° tilting system with suction cups to prepare the panel for

the covering of the lower part during the second passage

in the finishing line - Axis x and z of the bridge loader and unloader dedicated to electronic

control, driven by brushless motors to increase performance

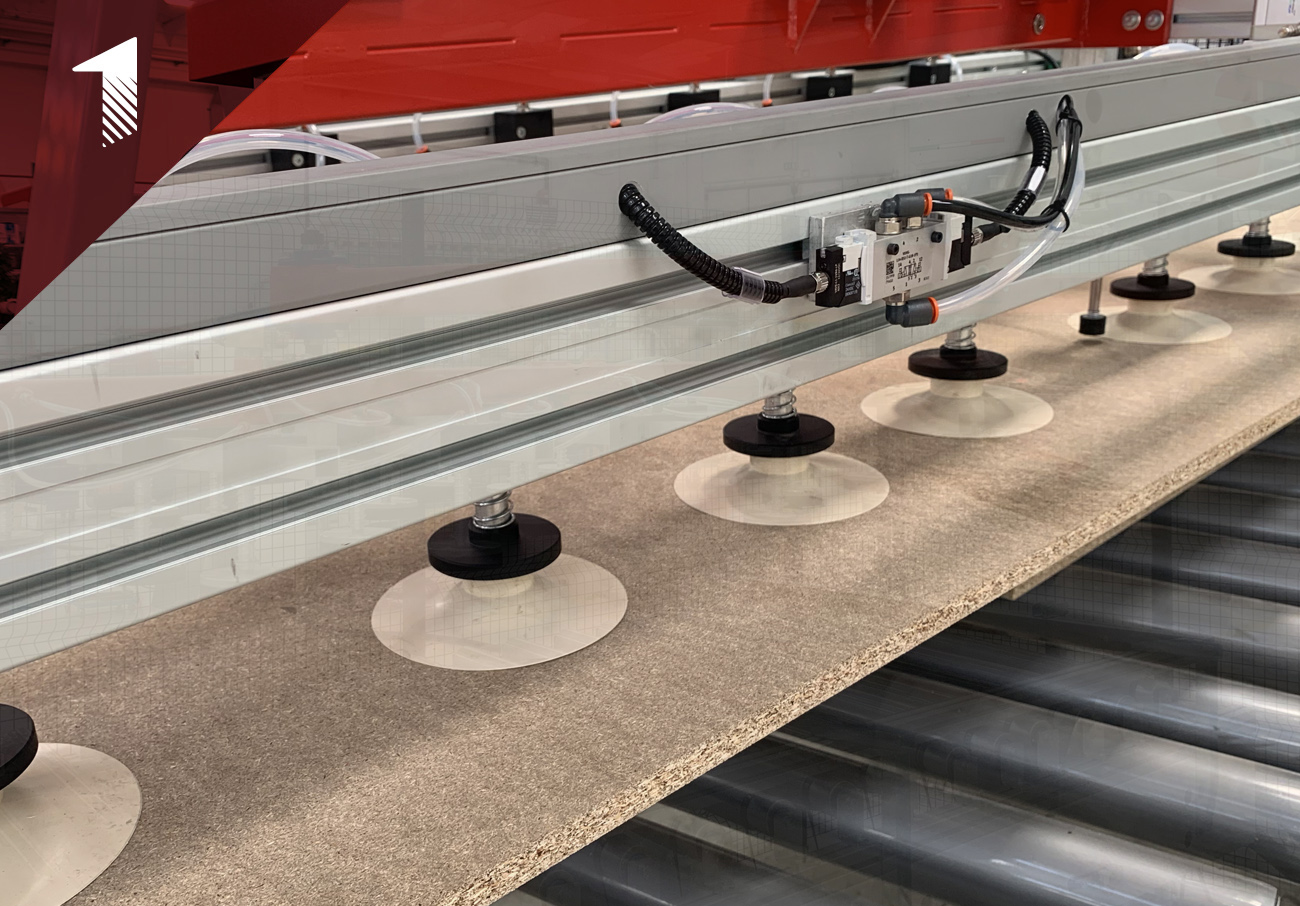

and positioning accuracy of picking and depositing of the machine - Panels gripping and depositing system with special stain-proof

and anti-halo suction cups for panels with glossy finish coatings - Machine management by plc with latest generation user friendly

touch screen keyboards for managing the parameters and functions

of the goods transport machine - Machine management by plc

Solution

The plant was designed by our technical department which, together with the software department, developed the technical solution for the operation and management of the complete line.

Benefits and results

The system allows you to automate the panel coating process, eliminating labor costs related to the loading and unloading of the material. The solution with the Portal plus model allows the handling of panels up to 200 kg while ensuring the speed necessary for the optimal operation of the production line.

WATCH THE VIDEO OF THE COMPLETE OPERATION OF THE MACHINE

A consultant at your service

Fabrizio Greco | Sales Director – Handling Systems