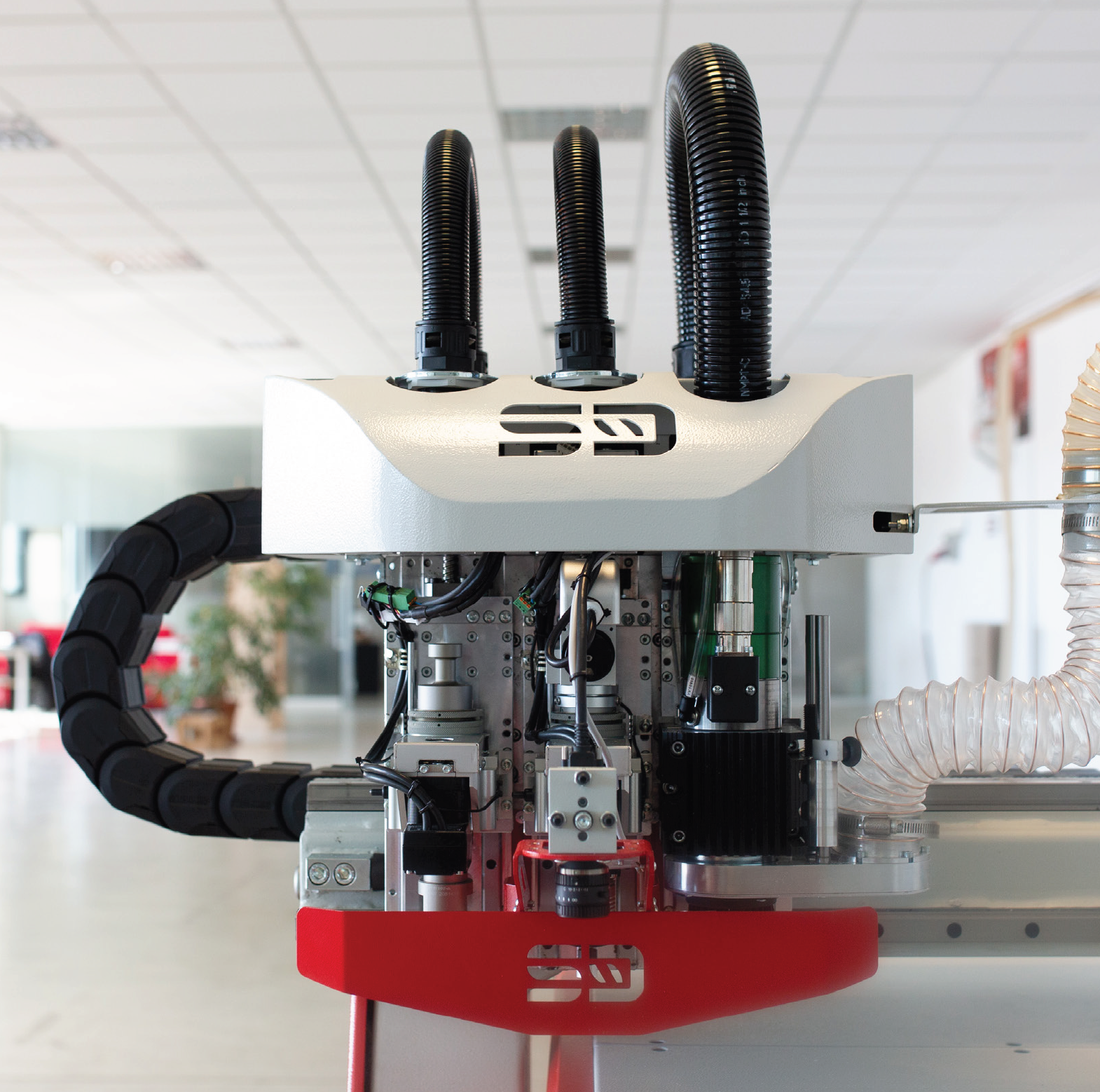

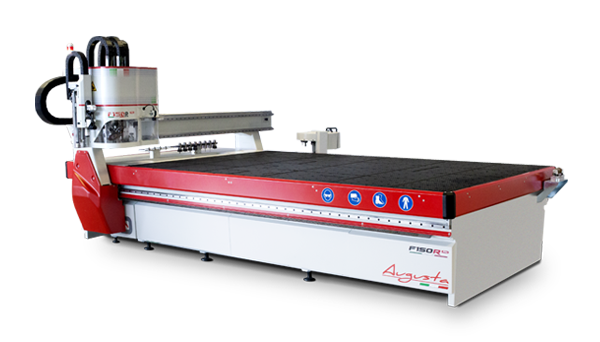

Augusta F50R PRO

Speed and accuracy

The supporting structure consists of a monolithic base in thick steel, strongly ribbed and extremely rigid. All the details are ground on high precision numerical controls which guarantee stability and quality over time.

The F50R PRO automatic plotter is extremely fast and precise in all situations with axis movement of 120 metres-minute and acceleration and deceleration up to 1,5 G.

DOWNLOAD THE F50R PRO CATALOGUE

A new updated catalog at your disposal to learn more about the new F50R PRO automatic cutting plotter by SD Italy.

Inside the catalog you will find all the information and innovations introduced by our R&D team. Evolve your business with our automatic cutting plotters.

Watch the video of F50R PRO

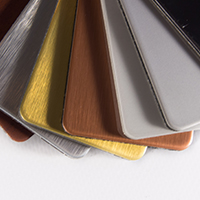

Leather

Rubber

Cardboard

PVC

Polyurethane foam

Gaskets

Alucobond

PTFE

Polycarbonate

Wood

Foam Rubber

Dibond

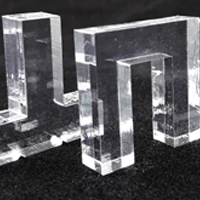

Plexiglass

Forex

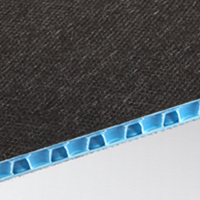

Polypropylene

Watch the videos dedicated to our work

Plexiglass

Cardboard

Polyurethane foam

Forex

Leather

Honeycomb polypropylene

Corrugated cardboard

RELATED PRODUCTS

Augusta F1R2 PRO

Digital die cutter

Augusta F150R PRO

Automatic cutting plotter

inFactory Suite

Automated interconnection system