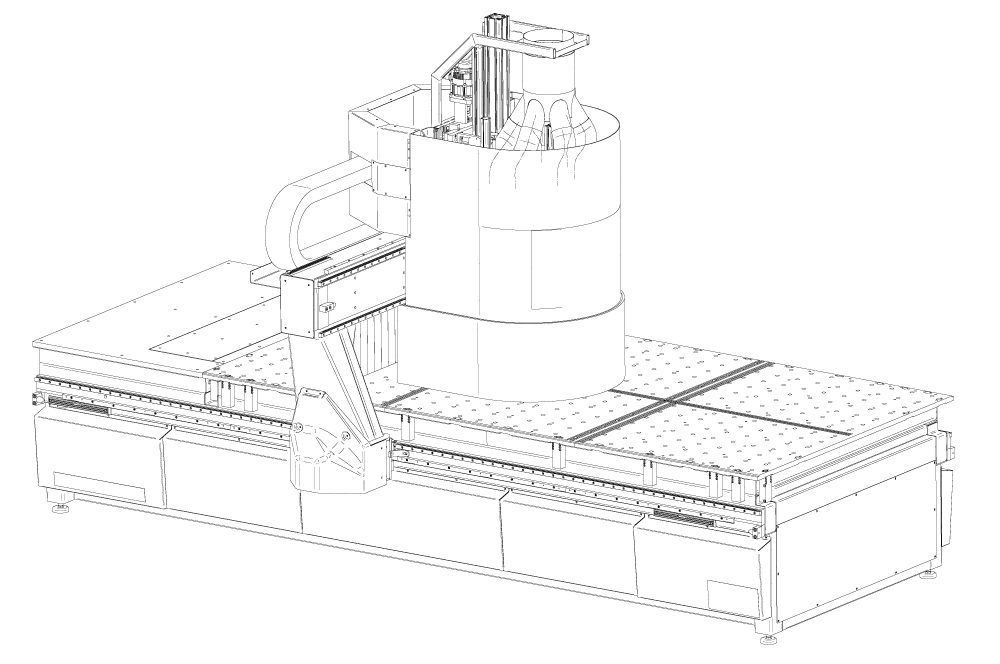

Augusta F300R

| Piece passage | Up to 350 mm |

| Power supply | Three-Phase 380/400 50 HZ |

| Tool change | Up to 13 positions |

| Working area | X 1720 – Y 1600 – Z 300 mm |

| X 3300 – Y 1600 – Z 300 mm | |

| X 7350 – Y 1600 – Z 300 mm | |

| X 3300 – Y 2100 – Z 300 mm | |

| X 5740 – Y 2100 – Z 300 mm | |

| X 7350 – Y 2100 – Z 300 mm | |

| X 9770 – Y 2100- Z 300 mm | |

| X 11380 – Y 2100 – Z 300 mm | |

| X 15400 – Y 2100 – Z 300 mm |

The bearing structure consists

of a high thickness steel monolithic base, well ribbed and especially rigid.

The particular structure, with very broad base has been designed to ensure stability and accuracy to the machine over time, in any work condition.

Stability

The mobile gantry structure consists of a solid single block which can be

anchored to the base, and slides on racks and prismatic guides equipped with recirculating ball bearings of the highest quality.

Precision

The fast and precise positioning of the mobile gantry structure (X axis) and operating units (Y-axis) is obtained with pinion and sloping toothed rack, which ensure the precise positioning of the operating unit along the Z axis.

Automatic lubrification

System for automatic lubrication of X, Y and Z axes, totally managed by numerical control. This option eliminates completely the need for manual routine maintenance of handling components.

Precision

The sturdy Gantry structure, combined with perfect mechanical dynamics and

the double motorization along the X axis of the mobile gantry structure controlled by Brushless Motors, allows obtaining the highest accuracy of positioning and very high

speed of movement with maximum results in terms of quality and finish. The catenary system integrated in the base allows the operator to enjoy the maximum efficiency of the machine.

The operating units are modular and can be combined.

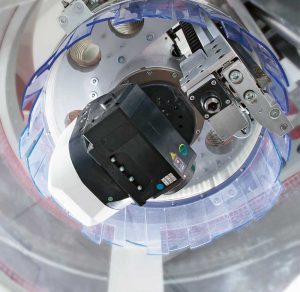

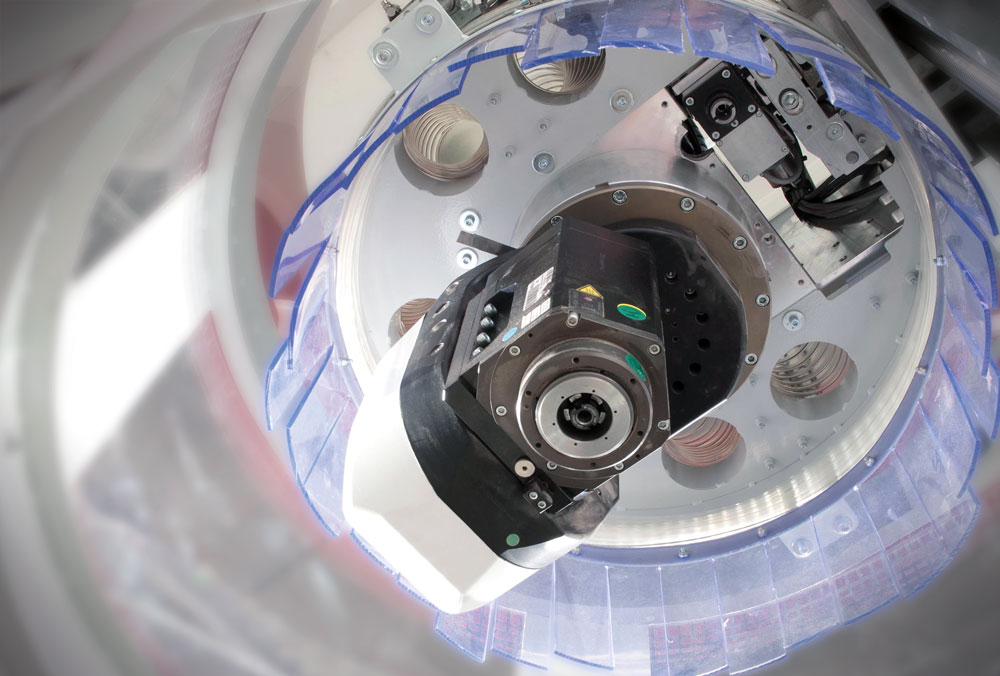

5-Axes electro-spindle

Operating unit with 5 interpolating axes, anchored to the mobile gantry structure ensures maximum stability during milling and excellent finishing quality even in the presence of heavy material removal. The unit guarantees full use of the work areas both with vertical spindle and horizontal spindle.

Electro-spindle specifications

Electrospindle with HSK 63F connection;

Rotation speed: 20.000/ 36.000 rpm;

Right, left rotation; Power 11 – 14 kW;

Liquid cooled.

AFT Power Group

The new power of the group AFT Power (vibrated or fixed knife cutting

managed directly from the CN) combined with the high flexibility of automatic tool change allows to manage heights and types of different material without any waste of time. In addition to the management of blades / cords and heads you have the chance to switch from the fixed to the vibrated cutting with a simple “click”.

Cooling system

The tool cooling system can be used with nebulized liquids, lubricants and with air Venturi cooling systems allowing direct cooling of the tool.

BLADES FOR LEATHER CUTTING

BLADES FOR POLYSTYRENE FOAM CUTTING

BLADES FOR PAPER AND CARDBOARD CUTTING

CUTTERS

Applications

- Aeronautics

- Furnishing

- Automotive

- Industrial gaskets

- Naval sector

- Packaging

- Leather and fabric

- Polymeric materials

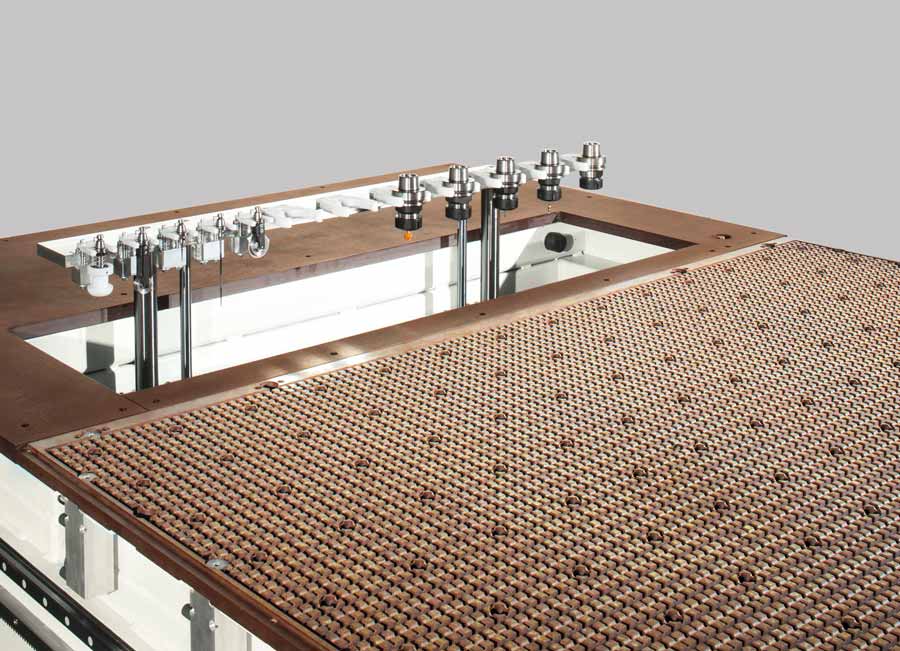

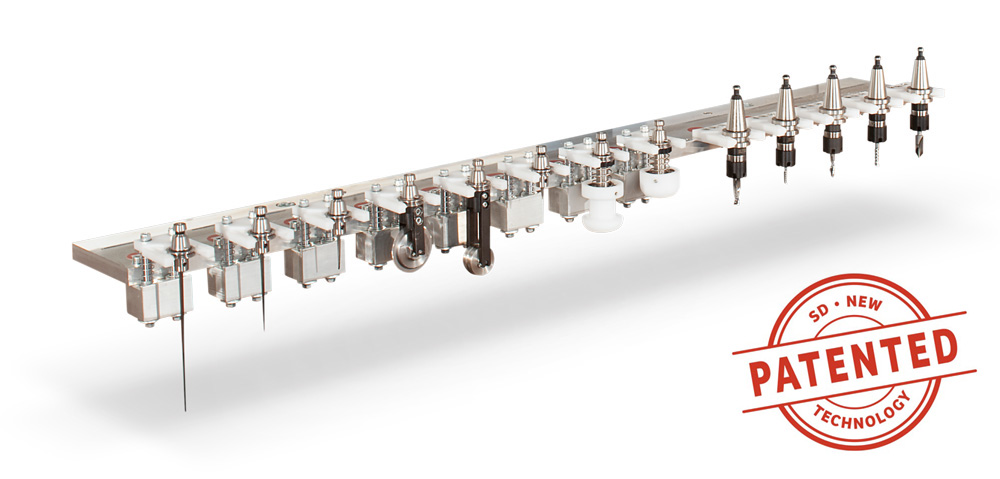

Up to 12-tool magazine, configurable according to customer requirements

Automatic tool change

The tool magazine interlocks the AFT units and milling unit.

Automatically controlled tool length

The device allows the operator to check automatically the length of the blade or milling-cutter to be used.

It is highly flexible and configurable with different panels, using supports or suction (H 125 mm) cups to ensure the best clamping of material to be precessed. The worktop consists of 24 independent vacuum areas selected by Numeric Control.

Mechanical marks

The retractable stops on the worktop allow the operator to perform a precise positioning of the material to be processed.

PC with new interface designed and developed by SD for a simple, effective and accessible programming even to those unfamiliar with the computer.

Automator

Programming of all operating units, Electro-spindle, AFT and AFL. Cad cam with management and importation of many types of files. Nesting with optimizations of cuts and milled. Preview of the workings to be performed on cuts of creasing and milling.

RELATED PRODUCTS

Augusta F1R2 PRO

Augusta F50R PRO

Augusta F150R PRO